Streamlined MCRQ Receiver

The Modulo Uno is a laser interferometer featuring a streamlined version of our rugged Multi-Channel Random Quadrature (MCRQ) optical design. Unlike its larger counterpart, the Quartet, which uses two detector arrays to independently register vertically and horizontally polarized components, the Modulo Uno utilizes a single detector. However, it offers more than just a smaller size compared to the Quartet. Its innovative optical design eliminates the need to split the probe beam for processing, allowing the Modulo Uno to operate efficiently with a lower-powered laser. This not only reduces construction costs but also enables testing on sensitive materials like composites (without a beam chopper), making it particularly well-suited for biomedical applications.

FEATURES.

Robust & Versatile

The Modulo does not require high accuracy optical components or positioning, making it exceptionally rugged.

Fiberized Optical Head

A versatile fiberized optical head is easily mounted to fit a variety of measurement conditions and can be set-up for a wide-range of stand-off distances.

Analog & Digital Outputs

The Modulo produces both an analog and digital signal proportional to surface displacement.

High Sensitivity on all Surface Types and Materials

A detector array together with high transmission optics result in high sensitivity. The Modulo produces a stable, demodulated signal even when processing a highly speckled beam. Measurements can be performed on any kind of surface, including rough, porous, rusted and mirror-like.

Rapid Inspection

Efficient electronic processing allows for measurement speeds up to meters per second.

Not Wavelength Dependent

The Modulo can be fitted with a range of internal laser wavelengths ranging from visible to infrared.

SPECIFICATIONS.

Technology

Multi-Channel Random Quadrature

Detection

Out-Of-Plane

Configuration

Optical Fiber

Laser Output

30 – 100 mW

NESD (out-of-plane motion)

Varies based on model specifications. Contact us for more information.

Detection bandwidth

Up to 20 MHz

Dimensions

400 x 170 x 165 mm

Weight

6.5 kg

Electrical requirements

110V / 220V

50Hz / 60Hz

TECHNOLOGY.

The idea behind Multi-Channel Random Quadrature was to develop a laser-ultrasound technology with a robust, compact design and a large depth-of-field capable of functioning effectively in a wide range of environments without loses in sensitivity, including on rough surfaces. With support from the National Science Foundation and NASA, we developed a novel interferometric design. By collecting and processing a multitude of speckles, the Modulo is fully functional in environments which would otherwise be unsuitable for most other laser ultrasound instruments.

More about Multi-Channel Random Quadrature

Design

Laser-based ultrasound receivers rely on interferometry. This means that two interfering beams are necessary for signal detection. A reference beam carries an ideal phase and amplitude profile, while a sample beam is formed by the reflection of the probe light from the sample surface, the contrast created by the interference of the two beams is where the information lies. An ultrasound signal wave, generally produced by a generation laser, introduces a displacement on the surface of the sample. This signal wave modifies the sample beam which is projected against the sample. The interference between the two beams makes it possible to determine the temporal dependence of vibrational surface displacement.

Common laser-based interferometer designs require both the reference and sample beams to be plane waves. However, for most LU systems the random phase distribution of speckles means that only a small portion of the reflected, scattered light can contribute to the amplitude of the measured signal, making the interference inefficient. This is especially true when scanning rough surfaces which tend to scatter the incident light. For most laser-based interferometer designs a highly speckled reflection beam means that most of the power of the probe beam reflected from the surface is unusable and as a result the detection sensitivity of the instrument drops sharply. Due to the limitations of their optical architecture most laser-based interferometers only collect a single or a few speckle in order to maintain phase coherence, which leads to a significant reduction of sensitivity on optically challenging surfaces.

To remedy the problem, the detection aperture size can be enlarged and an array of photodetectors used instead of a single detector such that the instrument collects multiple speckles. The sample beam, composed of multiple speckles, is mixed with the expanded reference beam and then projected onto arrays of photodetectors.

That’s where we come in with our proprietary Multi-Channel Random Quadrature (MCRQ) technology.

Our system does not rely on a standard quadrature detection scheme (which requires the detection of two complimentary signals with a 90° phase difference). MCRQ takes advantage of the random optical phase distribution, assuming that statistically half of signals registered by the photodetectors are in-quadrature and half are out-of-quadrature. The signals from multiple photodetectors (a detector array) are demodulated separately then summed together. This way the overall sensitivity of the measured signal remains high without the need for stabilization as the out-of-quadrature signals will not contribute to the resulting signal. To obtain exceptionally high sensitivity, our Quartet relies on two arrays of 25 photodetectors. Each signal recorded by the array is individually demodulated and processed. Relying on statistical speckle distribution to perform quadratic demodulation makes our MCRQ interferometers (the Quartet and Modulo series) highly sensitive, while forgoing the need for strict optical alignment protocol.

To further improve our systems’ flexibility, our MCRQ interferometers are fitted with a multimode optical fiber and optical head. The sample beam is projected through the fiber and then focused onto the surface being measured using the optical head’s lens system. A portion of the beam then reflects off the surface of the object before being collected by the same optical head and sent back through the fiber. The reference beam is made up of a small part (about 4–5 %) of the incident laser beam that is reflected by the end of the optical fiber. A small piezoelectric actuator is also attached to the end of the fiber, inside the optical head to vary the object path between the lens and the end of the fiber, such that a known Doppler shift based pilot signal is added to the sample beam. We use this pilot signal during processing to perform the sign correction. During backpropagation, the reference and sample beams interfere in the optical fiber.

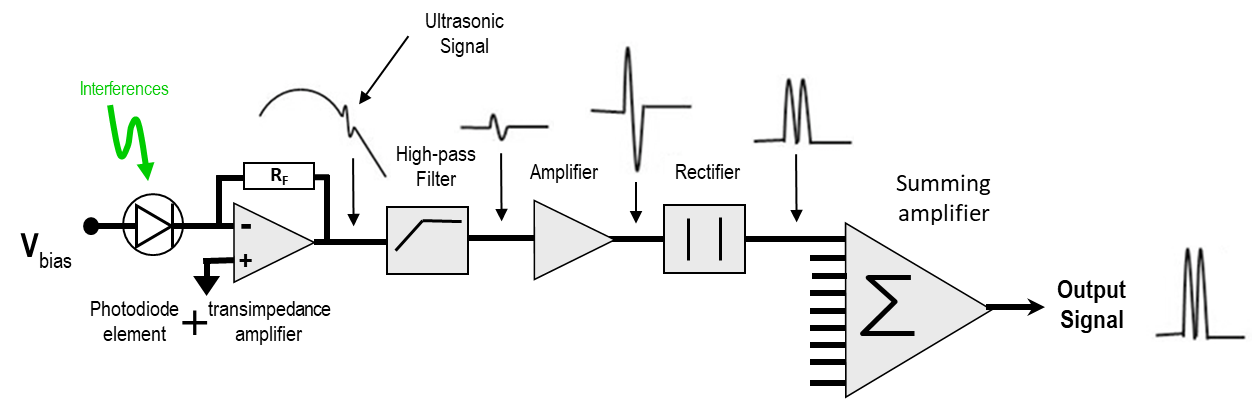

Demodulation

Our MCRQ interferometers use two possible demodulation schemes: a rectified demodulation, and a linear demodulation. The rectified demodulation involves high-pass filtering to remove low-frequency perturbations, followed by the amplification and rectification of the signal. All the individual signals are summed together to obtain the resulting signal. This first scheme efficiently rejects background noise, but the information on the direction of displacement is lost. The second demodulation scheme, or linear demodulation, involves a logic control which detects the signal phase by monitoring the pilot signal. Depending on whether the signal is in-phase or out-of-phase, the logic switches between the two, summing amplifiers to add the appropriate signals constructively. The switch is based on the previously mentioned low-frequency Doppler shift introduced by the piezo-ring attached to the fiber. The low-frequency signal is separated from the high-frequency signal and used to switch the summation logic circuit based on the low-frequency sign. In this way, the displacement direction of the signal is accurately recovered.

Rectified demodulation:

Linear demodulation:

Multi-channel laser interferometric method and apparatus for detection of ultrasonic motion from a surface

Interferometric method and apparatus for linear detection of motion from a surface

Laser intensity noise rejection for interferometric apparatus

APPLICATIONS.

Our systems have a multitude of potential applications. Listed below are a just few brief descriptions of feasibility studies done using our receivers. If you have any questions regarding applications, we would be happy to lend our expertise to your problematic.

Transducer Characterization Showing non-uniform Surface Displacement

Visible Non-uniform Surface Displacement

- Direct Laser Ultrasonic Measurement

- 5MHz Piezo with Pulse excitation (50Vpp).

- ≈ 4nm peak-to-peak surface displacement.

- Modulo:

- 30mW laser output with a wavelength of 1064 nm.

-

- NESD* on Piezo: ~ 5∙10-5nm/Hz1/2.

- NESD* on Piezo: ~ 5∙10-5nm/Hz1/2.

-

- 30mW laser output with a wavelength of 1064 nm.

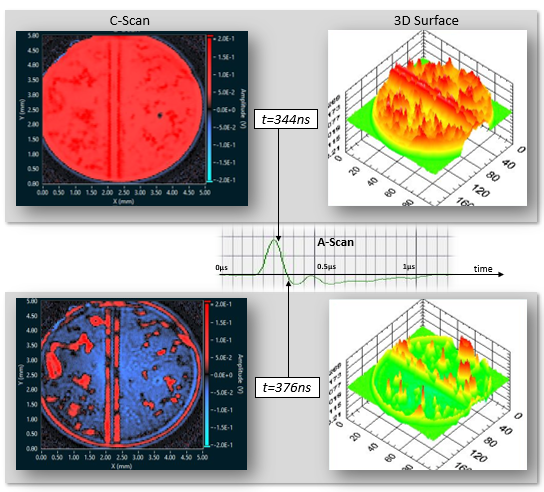

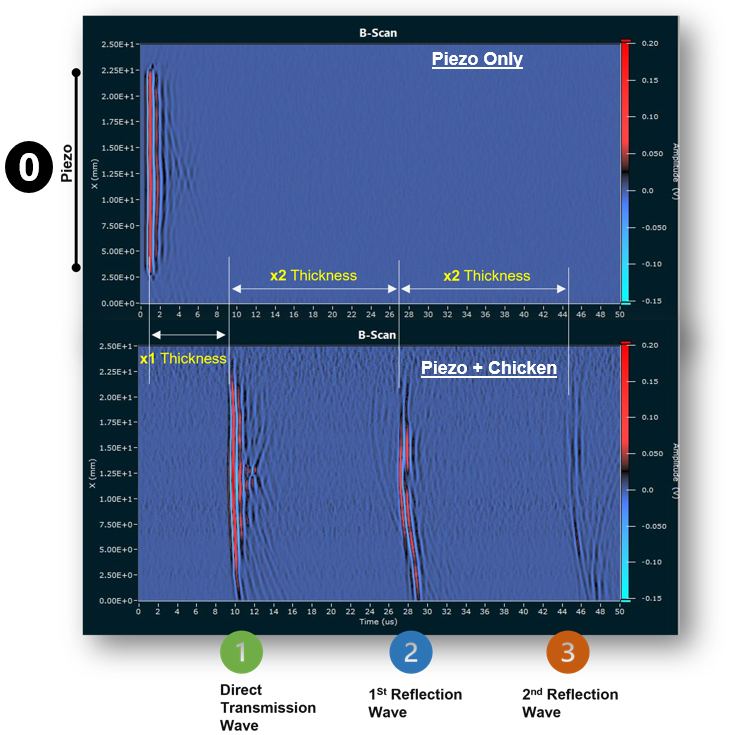

Animal Tissue Scan

Through transmission experiment

- 2.25MHz Piezo, 0.75” diameter

- Pulse excitation (50Vpp)

- Sample: Chicken breast, thickness ~ 12mm

- Corresponding surface displacement ~4nmpp

- Line scan across Piezo (+chicken)

- Modulo-Uno:

- Laser output: 30mW @ l=1064 nm

Noise Equivalent Surface Displacement (NESD) measurement on Chicken Breast Meat

- Stand-off distance =100mm

- Signal strength (Free mode) = 120mV/nm

- Calibration (Auto mode) = 100mV/nm

- Detection Bandwidth = 14MHz

– RMS Noise = 23mV

– NESD = 62∙10-6nm/Hz1/2